Standard Disclaimer:

This is an account of what I did with my vehicle

and my own comments. Any use of this information is at the user's risk.

This exercise was performed on a 1G-GTE MK III Supra but advice to hand

is that 7M digital dashes as they're basically identical and that the 1JZ

dash is only different in omitting the oil pressure gauge.

The instrument cluster of the MK III is a little more than a collection

of instruments to inform the driver. As part of the vehicle electronics,

if it falls into disrepair, it can be the source of operational failures.

This is particularly so as the No. 1 speed sensor signal (used in shift

control of the automatic transmission) comes via dash instrument electronics.

The desire to rid the gremlins from my recently rebuilt transmission (along

with annoyance at the infamous unreliability of the fuel guage) prompted

me to embark on removing and inspecting my instrument cluster. Mine is

a right hand drive vehicle.

Removal of the instrument cluster itself is not difficult, although

requires a little patience (that's what cars are for). From memory, I removed

-

the centre console facia and heater controls

-

the small panel to the right of the steering wheel which houses the fog

light switch

-

steering column trim pieces (4 panels) and covered the column with a soft

cloth to protect the instrument cluster face on removal. The steering column

was dropped to its lowest adjustment and extended to be farthest from the

dash.

-

the "under trim" of the dash pad over the cluster. The screws were easily

accessible in their recesses. The under trim piece was fragile and required

careful removal. I will have to replace some of the screw recess bases

to properly secure it again.

The instrument cluster was thus revealed with six fixing screws securing

it to the dash. Having removed the screws, I could move the cluster assembly

outwards and get my hand behind to remove the 4 or 5 connectors from the

back (actually, to push painful little tags, wriggle and cajole the larger

connectors with expressions of frustration). With the harness disconnected,

the assembly could be carefully maneouvred out from its "cave" and past

the steering wheel toward the passenger side of the cabin. |

Here

you can see the neat white plastic speed sensor housing fed by the top

speedometer cable (not visible here) and secured to the front cabin brace

member behind the instrument assembly (removed in the photo, of course).

The sensor itself is a simple Hall effect chopper assembly.

Here

you can see the neat white plastic speed sensor housing fed by the top

speedometer cable (not visible here) and secured to the front cabin brace

member behind the instrument assembly (removed in the photo, of course).

The sensor itself is a simple Hall effect chopper assembly.

Once

the instrument assembly is removed from the vehicle, I placed it face down

on a SOFT SURFACE (I did not want the ugliest scratched instrument facia

when I put it back) where the vent registers could be carefully removed

from it. These were held by a couple of screws and plastic clips. If anyone

can preserve the plastic clips, he / she deserves a medal.

Once

the instrument assembly is removed from the vehicle, I placed it face down

on a SOFT SURFACE (I did not want the ugliest scratched instrument facia

when I put it back) where the vent registers could be carefully removed

from it. These were held by a couple of screws and plastic clips. If anyone

can preserve the plastic clips, he / she deserves a medal.

Once

the final screw is removed and the front panels carefully separated from

the back shell, the front was revealed to consist of three layers (all

smoke and mirrors to make it look flash - well hopefully not smoke.). Particularly

as the casing is not sealed, these layers accumulated a layer of grime.

Carefully cleaning each with a SOFT cloth and a plastic cleaner (I used

one called Plexus I use on my motorcycle and helmet) made a HUGE difference

to the dash appearance.

Once

the final screw is removed and the front panels carefully separated from

the back shell, the front was revealed to consist of three layers (all

smoke and mirrors to make it look flash - well hopefully not smoke.). Particularly

as the casing is not sealed, these layers accumulated a layer of grime.

Carefully cleaning each with a SOFT cloth and a plastic cleaner (I used

one called Plexus I use on my motorcycle and helmet) made a HUGE difference

to the dash appearance.

On

the right hand side is the engine temperature bar graph indicator unit.

It is a separate circuit board which may be removed. Note though that it

is on an angle to match the fuel guage on the other side of the speedometer

but its fixing screws do not fix its position i.e. when re-installing it

it needs to be adjusted to match the fuel guage angle and then the fixing

screw tightened to secure it. The fuel guage is fixed to the same circuit

board as the speedometer, so it could not be adjusted.

On

the right hand side is the engine temperature bar graph indicator unit.

It is a separate circuit board which may be removed. Note though that it

is on an angle to match the fuel guage on the other side of the speedometer

but its fixing screws do not fix its position i.e. when re-installing it

it needs to be adjusted to match the fuel guage angle and then the fixing

screw tightened to secure it. The fuel guage is fixed to the same circuit

board as the speedometer, so it could not be adjusted.

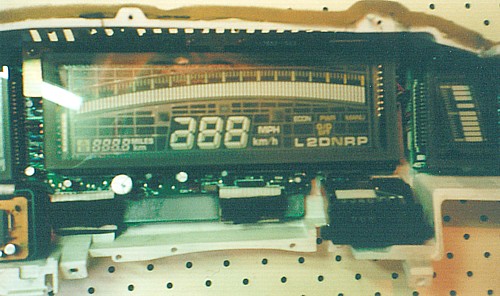

With

neither illumination nor masking, the speedometer unit showed all possible

displays. Sorry, anyone who wants to go over 399 kmh will need another

instrument (or convert to MPH but that just shifts it to a 399 MPH limit).

The odometer is a mechanical counter mechanism driven by an electric motor

on the lower right of the speedometer.

With

neither illumination nor masking, the speedometer unit showed all possible

displays. Sorry, anyone who wants to go over 399 kmh will need another

instrument (or convert to MPH but that just shifts it to a 399 MPH limit).

The odometer is a mechanical counter mechanism driven by an electric motor

on the lower right of the speedometer.  .

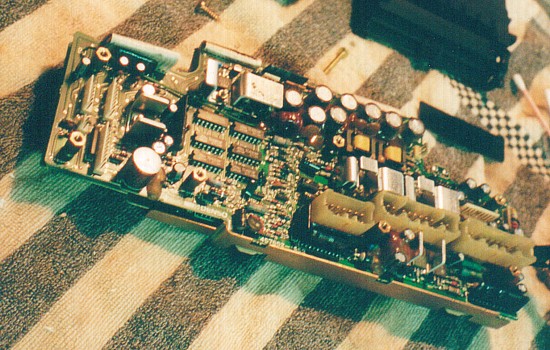

. The

screws exposed at the rear of the cluster shell were removed to lift out

the speedometer subassembly for inspection as the major wiring harness

connectors attach directly to this module. As this subassembly comprises

three stacked daughter boards with interconnecting ribbon cables, I was

not eager to disassemble it. However, if suspected electrical connection

problems continue, I would separate these boards to examine the connector

solder joints on the back of the board shown on top.

The

screws exposed at the rear of the cluster shell were removed to lift out

the speedometer subassembly for inspection as the major wiring harness

connectors attach directly to this module. As this subassembly comprises

three stacked daughter boards with interconnecting ribbon cables, I was

not eager to disassemble it. However, if suspected electrical connection

problems continue, I would separate these boards to examine the connector

solder joints on the back of the board shown on top. At

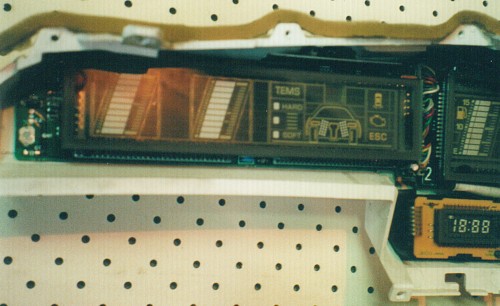

the left hand end of the cluster is the third instrument component which

comprises the boost and oil pressure guages as well as numerous vehicle

subsystem status indicators (TEMS, engine and doors). Note the earthing

pad on the far left of the component circuit board. This is the location

of the internal facia fixing screw. (Beats me how they assembled this part

... )

At

the left hand end of the cluster is the third instrument component which

comprises the boost and oil pressure guages as well as numerous vehicle

subsystem status indicators (TEMS, engine and doors). Note the earthing

pad on the far left of the component circuit board. This is the location

of the internal facia fixing screw. (Beats me how they assembled this part

... ) One

variation from the overall design is the seat belt warning light which

is separately mounted on the back shell and accommodated by a hole through

the boost etc instrument component. I guess this was only required in some

countries. All the same, I would have thought it cheaper to include it

in the component and simply not activate it ...

One

variation from the overall design is the seat belt warning light which

is separately mounted on the back shell and accommodated by a hole through

the boost etc instrument component. I guess this was only required in some

countries. All the same, I would have thought it cheaper to include it

in the component and simply not activate it ...